Home » Robotic Cleaning Integration

Robotic Cleaning Integration

Robots for Cleaning, Drying and Auto Load/Unload

integrate into existing automation processes.

Better Engineering is a certified integrator for robots and uses robots in multiple ways to bring automation to the highest level:

- For cleaning – A robot will move spray nozzles around a part to hit critical areas

- For deburring – A part can be deburred with high pressure water or special tooling

- For drying – A robot will pick up and rotate a part to empty pooled water and/or move dry nozzles around the part

- Auto loading and unloading – For all types of systems

Play Video

Play Video about Conveyor belt washer for cleaning compressor parts

Play Video

Robotic cleaning capabilities

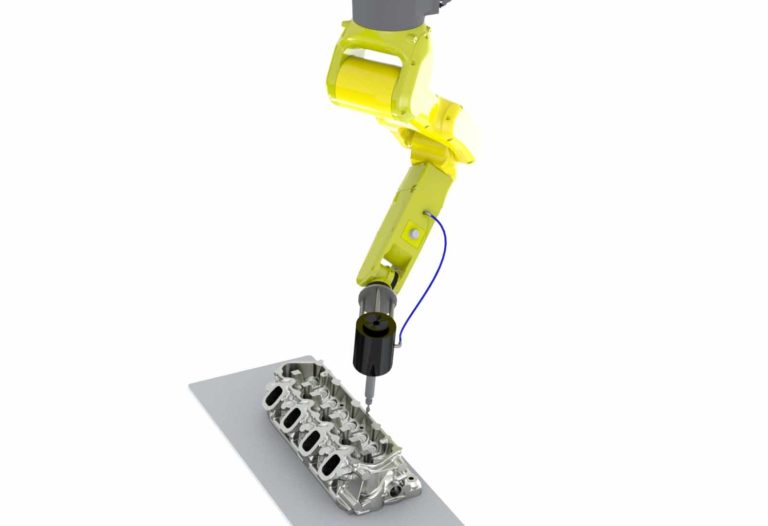

Rotary Tool Deburring

Six-axis robotic arms (such as FANUC’s LR Mate units) equipped with radially, axially compliant rotary tools have become very cost-effective solutions for deburring. These tools are pneumatically driven to provide torque, speed and compliance necessary for efficient automated removal of flash, parting lines and burrs. Robotic arms offer the extended reach in an easy to program platform for setting up the tool paths, and an auxiliary axis integrated to the FANUC controller (such as a turntable or linear table) can further extend tool reach. Workpieces are positioned and held in position during cycle by pneumatic shot pins and grippers. Where applicable the robotic arms with rotary tools offer an elegant alternative to the higher-complexity CNC deburring machines. Deburring process can then integrate into a cell that also cleans and dries the workpiece.

CO2 Blasting

Dust, oil and even sub-micron contaminants can be cleaned off of critical surfaces using gaseous CO2 or solid pellets dry ice blasting. This non-abrasive process is safer and produces no secondary waste as compared to other blasting methods. Solid dry ice sublimates on impact and lifts off and separates contamination from the cleaning surface. CO2 blasting is also an efficient and cost-effective surface preparation method applicable for plastics, metals and composites. Parts can be robotically manipulated over a static blaster or a robot with a blasting end effector can efficiently clean heavier workpieces.

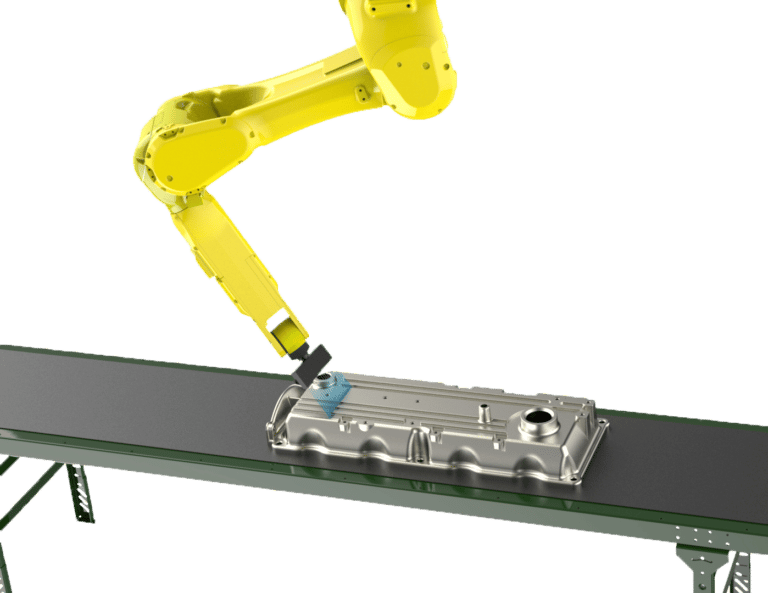

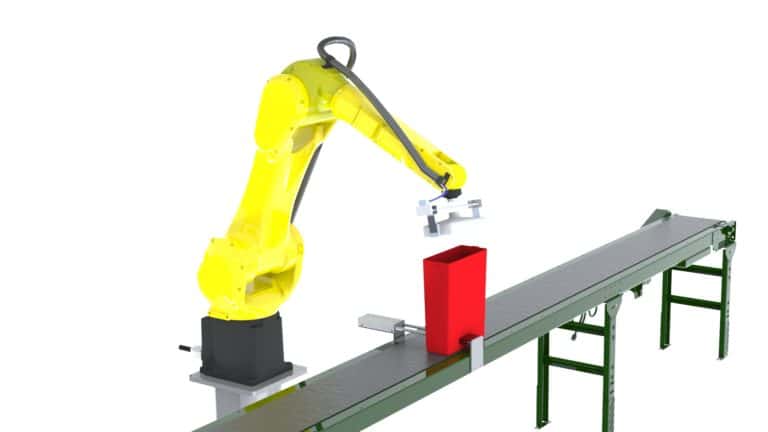

Bin Lid Removal

Automating the cleaning of reusable plastic containers (RPCs) is becoming practical and necessary for agriculture, food processing, medical waste, pharmaceutical applications. Full automation of cleaning in a conveyor (tunnel) system requires integration of material handling operations specific to totes and bins, such as bin lid removal. Six axis robotic arms offer the ideal platform for this bin lid removal/opening while other operations like stacking/de-stacking can be handled by customized mechanisms. Particularly in sharps container cleaning applications the complexity in the lid removal/opening step can be addressed with a robot equipped with a pneumatic end effector.