What is Metal Preparation and Passivation?

Metal preparation and passivation is the critical surface-finishing process for steel.

Stainless steel is undoubtedly one of the world’s most versatile and widely used materials. It’s durable, corrosion-resistant, and has numerous applications across various industries. However, suppose you’re looking to use stainless steel in an application where quality is paramount (such as aerospace or medical equipment). In that case, some essential steps must be taken before any parts can be produced.

To achieve the highest standards of quality and reliability, metal products must undergo a critical surface finishing process known as passivation. This simple process removes contaminants from the surface of metals, typically stainless steel. The purpose of the process is to increase the corrosion resistance of the metal, which is achieved by removing free iron particles and oxides that form on its surface.

Metal passivation can be performed by dipping or spraying a liquid solution onto your product and drying it off with compressed air or nitrogen gas. A final rinse in deionized water completes this important step in your manufacturing process!

Free iron and other contaminants left on the surface of stainless steel will corrode quickly if not removed, leading to fast failure – which can prove disastrous in high-performance applications such as medical instruments, aerospace components, or industrial equipment.

Can stainless steel deliver the corrosion resistance it optimally would provide without passivation?

Passivation is a critical step in the manufacturing process of stainless steel and requires an effective automated passivation system. In passivation, contaminants are removed from the surface of metals. These contaminants include carbon and hydrogen, which can increase corrosion resistance by forming protective layers on the metal’s surface. These layers prevent oxygen from reaching the metal and causing corrosion to occur.

Why is metal Passivation essential?

Steel parts are cleaned so they don’t rust. This makes them last longer. Passivation can be accomplished through different methods depending on what product you are producing or what equipment you have available at your facility. Not all passivation processes are created equal; some can take longer than others, while others may not be as effective at removing all contaminants from your steel product. Passivation is an essential process in the production of stainless steel products. It is important that you understand what passivation means, how it works, and how it affects the quality and reliability of your product. If you have any questions about how to passivate stainless steel with our products or services, please get in touch with us today!

What is the metal passivation process?

According to MIL-STD-753C, the passivation process is the last cleaning treatment used to eliminate iron from the surface of corrosion-resistant steel parts. This helps to achieve a more uniform formation of a passive surface, which increases corrosion resistance.

• Increased corrosion resistance of metal components for a longer life span

• Removal of excess iron particles, promoting improved performance

• More uniform formation of a passive surface that is highly resistant to corrosion

What metals can be passivated?

Passivation is a chemical treatment for stainless steel, aluminum, chromium, cobalt, gallium, gold, iron, lead, and other alloys that enhances the ability of the treated surfaces to resist corrosion. Passivated equipment and systems have many benefits, including removing contamination during processing.

When is the passivation of steel required?

It is crucial to passivate austenitic steel to create and maintain a consistent layer of chromium oxide on the surface of the stainless steel. This is especially important if the metal has undergone changes during manufacturing or product construction. If the system has become contaminated, it is necessary to perform passivation or re-passivation to fix the issue.

How do better engineering cleaning systems help with metal passivation?

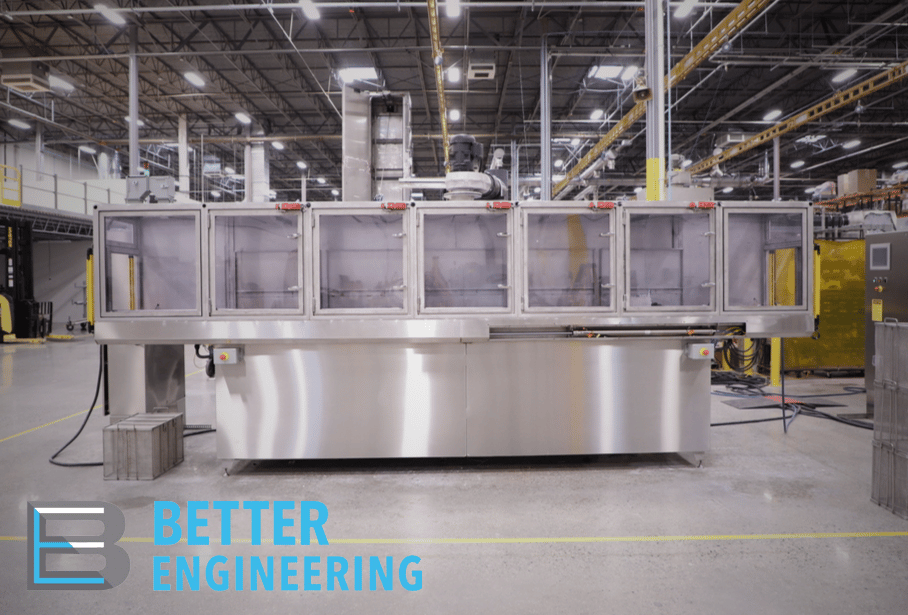

Better Engineering has been designing and manufacturing cleaning machines for 63 years to help companies achieve high standards of quality and reliability. Regarding metal products, we understand that preparation and passivation are critical surface-finishing processes that must be undertaken. Our cleaning machines are designed to remove contaminants from the surface of metals like stainless steel. Our company aims to increase your metal’s corrosion resistance by designing and building a machine that removes free iron particles and oxides that form on its surface.

Our automated passivation systems use a nitric or citric acid that removes all free iron and other contaminants from the substrate while maintaining its original integrity. The result is a metal surface with superior corrosion resistance and excellent heat transfer characteristics. Better Engineering’s automated passivation systems are commonly designed as monorail, turntable, or immersion washers.

Contact a system specialist today for more information about how we can help.