Home » Ammunition & Guns Parts Cleaning

It is imperative that ammunition and weapons be properly cleaned in order to be in optimal condition.

With Better Engineering’s casing cleaning machine and gun parts washer, your ammunition and gun parts cleaning processes produce reliable, safe products while streamlining your manufacturing processes.

Gun Parts Cleaning

The fastest way to clean your gun parts is with the Better Engineering firearms degreasing machine, designed to be more potent than the competition. In sum, our proprietary machinery powerfully cleans and degreases your components faster and better than any other industry’s technology. Ensure your guns are safe for use and restored to factory cleanliness.

Ultrasonic Washer for Firearm Degreasing: Better Engineering’s immersion, dip-tank, and washers fully immerse and ultrasonically clean components to ensure all blind holes or crevices are sufficiently cleaned. Once submerged, Better Engineering’s aqueous-based solution is either agitated around the part or sprayed under immersion, thoroughly cleaning and removing all debris.

ammunition parts cleaning

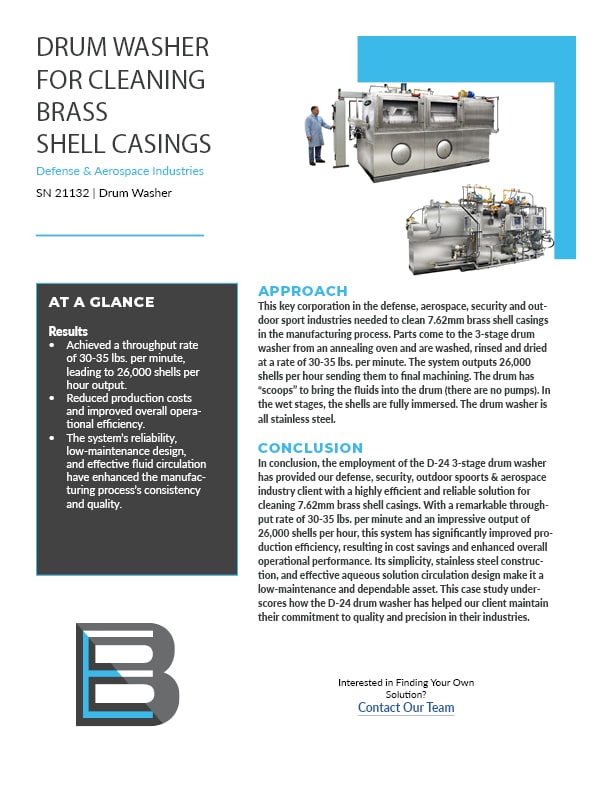

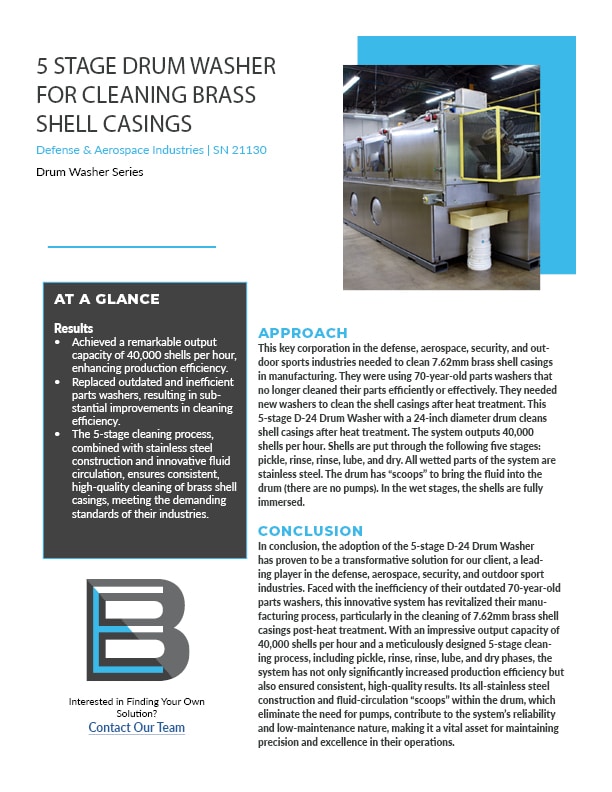

Better Engineering offers a variety of robust drum washers that combine spray and immersion technology. Most notably, our drum washers are highly efficient and can clean thousands of parts per minute.

Altogether, BE’s drum washers for ammunition parts cleaning often contain multiple stages such as a wash, rinse, acid pickle (oxide removal), brightening, lubricating, demagnetizing, and heated dry stages. Overall, BE systems remove heavy greases, lube, oils, soil, and burnt-on carbon materials.

Drum Washers for Ammunition: Drum washers are ideal for ammunition and brass casing cleaning. Our washers are typically used for high-volume, continuous cleaning and drying small parts. Drum washers clean by tumbling pieces along a helix welded on the interior of the drum, which conveys components forward through one or more cleaning stages.

FAQs for Ammunition and Gun Parts Cleaning

My company has footprint constraints. Would a drum washer work for me? Better Engineering’s parts washers are all modular and designed for flexibility. Our washers are modular and can be designed to fit any sizing constraints. Customers can tailor their parts washers without the risk and expense of customization using standard modules and accessories.

Can a drum washer combine immersion and spray? Yes. The wet stages can have spray, immersion, or both to ensure a complete clean.

Drum Washers for Ammunition and Gun Parts Cleaning

Drum washers are ideal for ammunition and brass casing cleaning. These washers are used for high-volume, continuous in-line cleaning and drying small parts. Drum washers clean by tumbling pieces along a helix welded on the interior of the drum, which conveys components forward through one or more cleaning stages.

Immersion Washers For firearm and Ammunition degreasing

Better Engineering's immersion, or dip-tank, washers immerse components to ensure all blind holes or crevices are sufficiently cleaned. After submersion, Better Engineering's aqueous-based solution is either agitated around the part or sprayed under immersion, thoroughly cleaning and removing all debris.