Material Handling

In the world of industrial parts washing, efficient and precise material handling ensures components move seamlessly through the cleaning process. At Better Engineering, we introduce a comprehensive spectrum of automated washing material handling methods and parts cleaning equipment designed to orchestrate the flawless transport, manipulation, and positioning of parts during the cleaning journey. Our array of material handling systems not only streamlines operations but also prioritizes safety and productivity, ensuring your operations function at their peak performance.

Material Handling for Automated Part Washing

Better Engineering introduces a spectrum of material handling methods and equipment, orchestrating the seamless transport, manipulation, and positioning of components during cleaning. Our array of material handling systems harnesses unparalleled efficiency, safety, and productivity for industrial parts washers.

Automated Washing Conveyor Systems

- Conveyor Types: We offer various conveyance types, including pallets, roller, belt, and chain.

- Automated Loading and Unloading: Integrating with robotic systems, conveyor systems reduce manual labor and increase efficiency.

- Flexibility: Can handle various part sizes and configurations, making them versatile for different cleaning applications.

Robotics & Robotic Automation Capabilities for Conveyor Washing Systems

- Precision and Consistency: Robots handle parts accurately and uniformly, ensuring consistent cleaning results.

- Flexibility: Programmable to handle different part types and adapt to changing production requirements.

- Reduced Human Intervention: Robotic automation lowers reliance on manual labor, improving workplace safety and reducing labor costs.

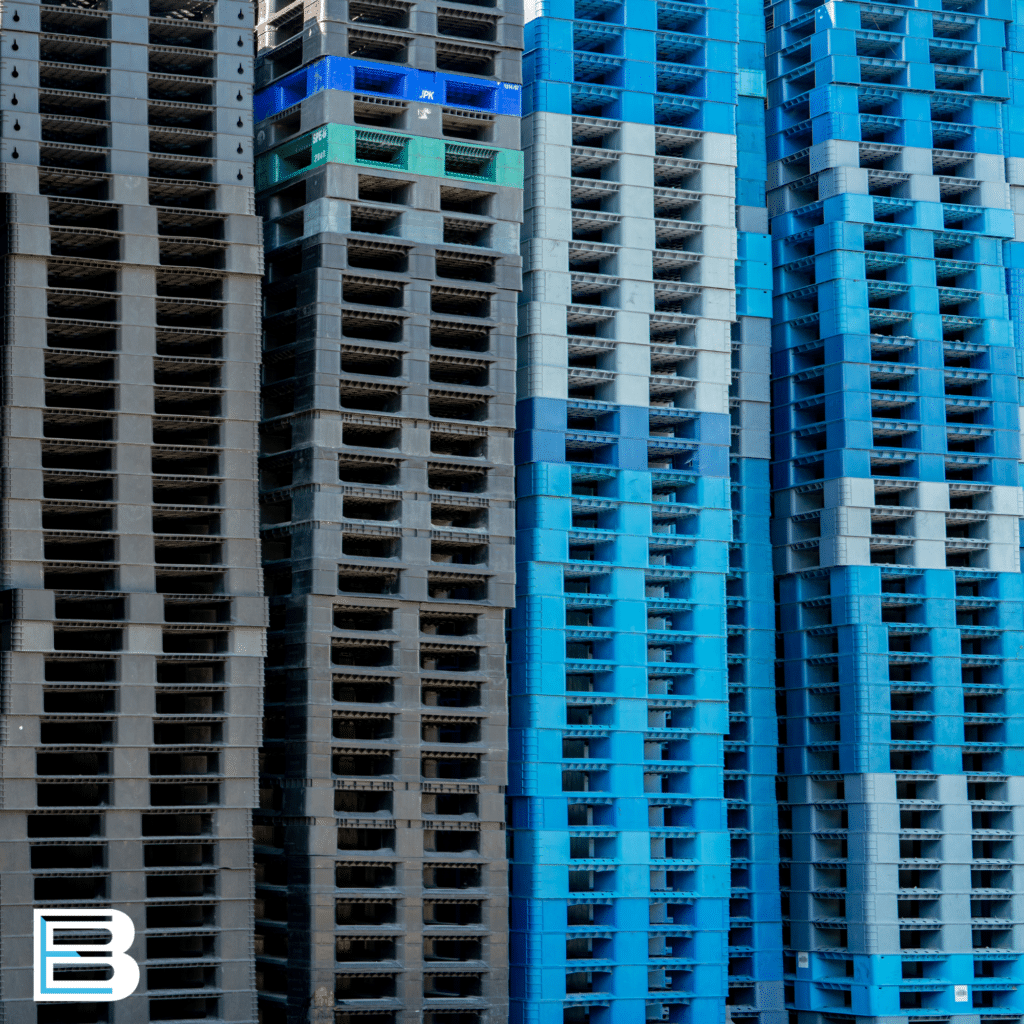

Cleaning Pallet Handling Systems:

- Batch Processing: Pallets allow parts to be processed in batches, optimizing cleaning capacity and throughput.

- Streamlined Workflow: Integrates well with parts washers, creating a seamless and organized cleaning workflow.

- Space Efficiency: Automated stacking and de-stacking pallets optimize storage space and inventory management.

Automated Bin Flipping Systems:

- Thorough Cleaning: Bin flipping ensures cleaning agents reach all surfaces inside the containers, resulting in effective cleaning.

- Labor Savings: Automated bin flipping reduces manual handling and labor requirements, leading to cost savings and increased worker safety.

- Process Optimization: Properly cleaned bins contribute to consistent cleaning results and reduce the risk of contamination in subsequent processes.

Efficiency, safety, and productivity are the guiding principles behind Better Engineering’s material handling solutions for automated part washing. Material handling systems serve as the backbone of industrial parts washers, ensuring that your production processes run smoothly, consistently, and with the utmost precision. Trust in Better Engineering to elevate your manufacturing operations through cutting-edge material handling solutions.