Home » Logistics and Distribution

Industrial Tray WAsher for Distribution, Logistics & Fulfillment Centers

Distribution, Fulfillment & Logistics

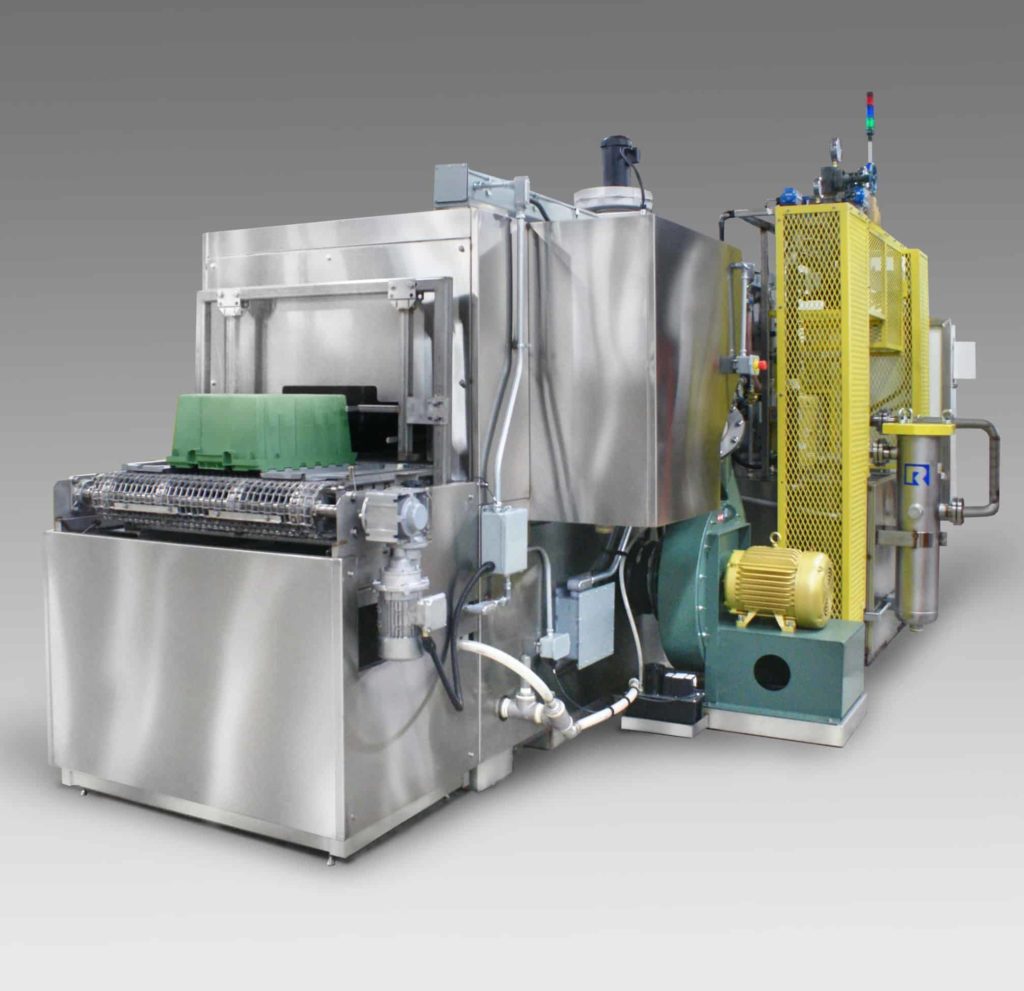

Better Engineering is a leading manufacturer of industrial tray washers and pallet washing systems explicitly designed for cleaning and sanitizing plastic pallets, totes, trays, RPCs, bins, and other small load carriers. BE understands that these containers come in various shapes and sizes and have different cleaning requirements. We work closely with companies to design an industrial tray washer and pallet washing system specifically for their particular application. Our modular systems may be designed with a combination of wash, rinse, sanitize, and dry stages, as well as different configurations such as multi-lanes, return conveyors, adjustable rails, etc., to meet your needs.

Items move between buyers’ and supplier’s facilities, and come into contact with various contaminants along the way, thereby needing to be cleaned with an efficient industrial tray washer. Dirt, grime, and grease can accumulate on pallets and totes, as well as food particles stored or transported. In addition, viruses and bacteria linger on surfaces, which can cause product contamination. Container and pallet cleaning is an essential consideration for any operation and is crucial for those handling food or requiring sanitary conditions.

Allowing dirt, grime, grease, and other contaminants to settle on pallets, totes, and other small load carriers will reduce their lifetime. In some instances, it can create unsafe handling conditions and can contaminate products. When working with food, pharmaceutical, or chemical products to ship, you need to clean and sanitize plastic pallets and containers for reuse effectively.

Industrial Tray WAshers

A logistics company is responsible for ensuring that clients’ products are not contaminated. An automatic washer is a faster and more effective method for cleaning and sanitizing large quantities of pallets and containers than manual cleaning. Also, sanitizing plastic pallets and containers requires specialized cleaning methods not attainable with manual cleaning. It means ensuring that the microorganisms are almost entirely removed without using harsh chemicals like bleach that could contaminate food or damage other products.

Heavy Duty Pallet Washing systems

Get peace of mind in knowing that your items are clean and free from any hazards.

Plastic pallets, totes, trays, RPC’s (reusable plastic containers), bins, and other small load carriers are used daily in warehousing, material handling, and logistics/transportation.

Better Engineering's sanitary line of stainless steel cleaning systems are built to the highest hygienic standards with industry-leading capabilities.

Automated pallet washing systems and industrial tray washers provide consistency and reduce the margin of error present with manual labor, helping you meet government regulations and guidelines. Our systems are hygienic by design, featuring stainless steel construction, full internal welds, complete access, and compliance with 3-A standards. Our machines meet all regulatory standards set by FSMA, HACCP, and GMP, ensuring products are free of physical, allergenic, chemical, and biological hazards.

OUR PROMISE TO QUALITY

Better Engineering’s sanitization machines are built to last. Our industrial tray washers offer the highest quality levels with trackable and repeatable results that don’t change over time. Our research lab can demonstrate the full potential of our washing and sanitizing systems using your containers. Mail us the items you would like cleaned, and we will test them to find the best machine recommendation for you. We guarantee that we’ll find a solution that meets all of your needs– it’s part of our commitment to customer satisfaction.

Company

60 Years Experience

Quality

BE develops innovative solutions to build critical automated cleaning systems for virtually every industry.

Plastic Pallets

Buckets

Lugs

Racks

Totes

Cages

Trays

Trucks

Reusable Plastic Containers (RPCs)

Machine Parts

Bins & Vats